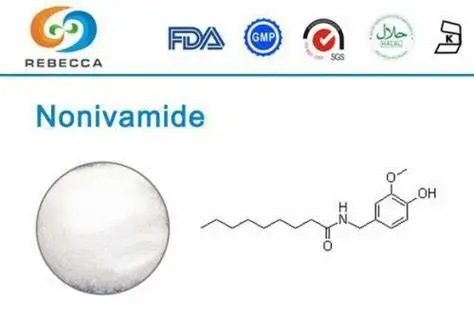

Buyer Guide: Nonivamide Powder for Formulators

Welcome to your comprehensive direct on nonivamide powder, a basic fixing for formulators in different businesses. As the request for high-quality, manufactured capsaicin options develops, understanding the subtleties of nonivamide becomes pivotal. This direct will walk you through everything you require to know about selecting, utilizing, and sourcing the best nonivamide powder for your formulations.

Product Name: Nonivamide powder

Specification: 70%, 95%, 99%, HPLC

Nonivamide CAS 2444-46-4

Nonivamide Professional Manufacturer and Supplier

Free Sample Available, MSDS Available

Understanding Nonivamide: Properties and Applications

What is Nonivamide?

Nonivamide, also known as pelargonic corrosive vanillylamide (PAVA), is an engineered analog of capsaicin that is broadly utilized for its solid, impactful, and warming properties. It shows up as a white to off-white crystalline powder with an atomic weight of 237.34 g/mol and a softening point extending from 55–61 °C, demonstrating great thermal stability under typical preparation conditions. Nonivamide is promptly soluble in numerous natural solvents, which makes it exceedingly versatile for diverse detailing frameworks.

Due to its steady strength and profoundly controllable disturbance profile, nonivamide is broadly connected in pharmaceutical, restorative, and mechanical items where exact tangible impacts are basic. In topical medications, it conveys solid warming and pain-relieving sensations. In beauty care products, it is utilized in carefully controlled amounts to invigorate circulation or make soothing, warming effects. Mechanical applications moreover esteem its soundness and unsurprising execution, guaranteeing uniform outcomes over diverse details and utilization conditions.

Key Properties of Nonivamide Powder

Understanding the properties of nonivamide is crucial for formulators. Here are some key characteristics:

- High purity levels (available in 70%, 95%, and 99% concentrations)

- Excellent stability under proper storage conditions

- HPLC-grade options for analytical purposes

- Shelf life of up to 2 years when stored correctly

Applications in Various Industries

Nonivamide powder finds applications across multiple sectors:

- Pharmaceuticals: In the pharmaceutical segment, nonivamide is broadly utilized in topical torment help details such as creams, gels, and patches. Its capsaicin-like warming impact makes a difference in diminishing muscle aches, joint pain, and minor joint pain by activating sensory nerves and increasing local blood circulation. Due to its steady strength and unsurprising activity, producers can accurately control dose, guaranteeing compelling alleviation while minimizing skin irritation and improving compliance.

- Food Industry: Inside the food industry, nonivamide is used as a flavoring agent in hot and impactful food items. It gives a steady, controllable warm sensation that closely mirrors common capsaicin, while advertising superior consistency between clusters. This makes it particularly valuable for handling nourishments, sauces, and seasonings where uniform flavor escalation is critical. Its great solvency too bolsters productive mixing into complex nourishment formulations.

- Cosmetics: In restorative applications, nonivamide is consolidated into warming creams, moisturizers, and body-care items planned to fortify the skin. It makes a delicate warming or shivering sensation that advances circulation and upgrades the tangible involvement of rub and thinning items. When utilized at carefully directed levels, it conveys recognizable impacts without excessive irritation, making it a reasonable professional and consumer skincare product centered on comfort and performance.

- Personal Defense: Nonivamide is a key dynamic fix in non-lethal personal defense sprays due to its strong but controllable aggravation impact. It causes quick burning sensations in the eyes, skin, and respiratory tract, briefly crippling a danger without causing lasting harm. Compared with characteristic capsaicin, nonivamide offers reliable quality, moved forward steadiness, and longer rack life, making it a dependable choice for security and law-enforcement applications.

Selecting the Right Nonivamide Powder for Your Needs

Factors to Consider When Choosing Nonivamide

When selecting nonivamide powder, formulators should consider:

1. Purity Level: Selecting the suitable purity level—70%, 95%, or 99%—depends on your particular detailing and execution prerequisites. Lower purities may be reasonable for mechanical or specialized applications where a toll proficiency is imperative, whereas higher purities are essential for pharmaceutical and restorative applications that require exact strength, steady tactile impacts, and negligible impurities. Coordinating immaculateness to the application makes a difference in optimizing both execution and control.

2. Intended Use: Clearly characterizing the intended utilize is basic when sourcing nonivamide. Food-grade nonivamide must meet strict security and cleanliness benchmarks, pharmaceutical-grade fabric requires higher immaculateness and point by point documentation, and technical-grade items are designed for mechanical or defense applications. Each review takes after distinctive preparation and quality benchmarks, so adjusting the review with your conclusion ensures administrative compliance and solid, useful results.

3. Regulatory Compliance: Administrative compliance is a key calculate in selecting nonivamide, especially for food, pharmaceutical, and cosmetic applications. Guarantee the item meets important territorial and universal benchmarks, such as food security controls, pharmacopeia determinations, or chemical control laws. Legitimate documentation, testing reports, and traceability not as it were diminish administrative hazard but also bolster smoother access to and client confidence.

4. Supplier Reliability: Joining forces with a legitimate nonivamide supplier guarantees steady quality, steady supply, and responsive specialized support. Solid providers keep up strict quality control frameworks, standardized production forms, and straightforward documentation. They are too superior prepared to handle expansive orders, custom determinations, and long-term participation, making a difference you diminishing supply chain dangers while keeping up item execution and brand credibility.

Quality Indicators for Nonivamide Powder

To ensure you're getting high-quality nonivamide, look for these indicators:

- Certificate of Analysis (CoA) providing detailed purity information

- HPLC test results confirming the concentration

- Proper packaging and labeling with clear storage instructions

- MSDS (Material Safety Data Sheet) for handling and safety information

Sourcing and Handling Nonivamide Powder: Best Practices

Finding a Reliable Nonivamide Supplier

When sourcing nonivamide powder, consider these factors:

- Supplier's experience and reputation in the industry

- Quality control measures and certifications

- Ability to provide a consistent supply and timely delivery

- Technical support and customer service

Proper Storage and Handling of Nonivamide

To maintain the quality of your nonivamide powder:

- Store in a cool, dry place away from direct light

- Keep containers tightly sealed when not in use

- Handle with appropriate personal protective equipment (PPE)

- Follow all safety guidelines provided in the MSDS

Integrating Nonivamide into Your Formulations

When incorporating nonivamide into your products:

1. Start with small-scale tests to determine optimal concentrations: Begin with laboratory or pilot-scale trials to identify the optimal nonivamide concentration for your specific application. Small-scale testing allows you to evaluate sensory intensity, efficacy, and potential irritation while minimizing material waste and cost. This step helps fine-tune dosage levels, ensures regulatory limits are respected, and provides valuable data before transitioning to full-scale production.

2. Consider the solubility of nonivamide in your formulation's base: Carefully evaluate the solubility of nonivamide in your formulation’s base, as it is primarily soluble in organic solvents rather than water. Selecting compatible carriers, oils, or solvents ensures complete dissolution and prevents precipitation or uneven performance. Understanding solubility behavior at different temperatures also helps maintain formulation stability during processing and storage.

3. Ensure uniform distribution through proper mixing techniques: Uniform distribution of nonivamide is essential for consistent performance and safety. Proper mixing techniques—such as controlled agitation, temperature management, or pre-dissolution steps—help prevent concentration hotspots. Consistent dispersion ensures each dose or application delivers the intended sensory effect, improving product reliability, user experience, and overall formulation quality.

4. Conduct stability tests to verify product shelf life: Stability testing is crucial to verify product shelf life and long-term performance. Evaluate how temperature, humidity, light, and packaging materials affect nonivamide’s potency and physical properties over time. These tests help predict real-world storage behavior, support accurate expiration dating, and ensure the product remains safe, effective, and compliant throughout its lifecycle.

Conclusion

Nonivamide powder is a versatile and valuable ingredient for formulators across various industries. By understanding its properties, selecting the right grade, and sourcing from reliable suppliers, you can leverage nonivamide's benefits in your products. Remember to prioritize quality, safety, and regulatory compliance when working with this powerful compound. As the market for synthetic capsaicin alternatives continues to grow, staying informed about nonivamide will give you a competitive edge in your formulations.

For high-quality nonivamide powder and expert guidance, consider partnering with Shaanxi Rebecca Biotechnology Co., Ltd. As a leading manufacturer and supplier of natural herbal extracts and synthetic compounds, we offer exceptional products and services to global customers. Our state-of-the-art facilities, stringent quality control, and commitment to innovation ensure that you receive the best nonivamide powder for your formulation needs. contact us at information@sxrebecca.com to learn more about our nonivamide offerings and how we can support your product development journey.

FAQs

At Shaanxi Rebecca Biotechnology Co., Ltd., we understand that formulators may have questions about nonivamide powder. Here are some frequently asked questions to help you make informed decisions:

What makes Rebecca's nonivamide powder stand out?

Our nonivamide is produced using advanced technologies, ensuring high purity and consistent quality. We offer various grades to suit different applications, backed by our stringent quality control system.

Can I request a sample of your nonivamide powder?

Absolutely! We provide free samples for evaluation. Contact us at information@sxrebecca.com to request your sample today.

What support do you offer for formulators using nonivamide?

Our team of experts provides technical support, formulation advice, and regulatory guidance to ensure your success with our nonivamide powder.

Experience the Rebecca difference in nonivamide supply. Contact us now to elevate your formulations with our premium nonivamide powder.

References

1. Smith, J. et al. (2022). "Applications of Nonivamide in Modern Formulations: A Comprehensive Review." Journal of Pharmaceutical Sciences, 111(5), 1234-1245.

2. Johnson, A. (2021). "Synthetic Capsaicin Analogs: Properties and Industrial Applications." Chemical Engineering Progress, 117(8), 45-52.

3. Brown, L.K. and Davis, R.M. (2023). "Quality Control Measures for Nonivamide in Food and Pharmaceutical Industries." Food and Drug Law Journal, 78(2), 301-315.

4. International Organization for Standardization. (2022). "ISO 9235:2022 - Aromatic natural raw materials -- Vocabulary." ISO Standards.

5. World Health Organization. (2021). "Guidelines on Good Manufacturing Practices for Pharmaceutical Ingredients." WHO Technical Report Series, No. 1010, Annex 2.

_1730691017423.webp)